What is a Truck Roll (and how to reduce their cost)

Wasting time fixing simple issues or doubling back to get the right tools because of a misdiagnosed problem is frustrating for field service technicians and costly for your business.

Unnecessary dispatches, also called truck rolls, cost time and money that your company could save without impacting performance or quality of service.

In this article, we’ll go over how to optimize truck rolls and cut back on unnecessary dispatches. We’ve also provided a cost calculator so you can see for yourself how much you’ll save.

A truck roll is when a field technician gets dispatched to a customer or other field agent’s location to solve a problem. That could mean anything from fixing broken equipment to walking through a difficult installation.

How many times have you sent a tech into the field to address a customer complaint only to find out the problem was simple? Maybe the tech needed to plug in the computer, flip a switch, or select the right settings? Or maybe there was an issue the tech needed to fix but they didn’t have the tools on hand because they went in blind? Avoidable truck rolls end up being a huge drain on resources.

But there is a viable solution to reducing these costs.

Technicians can often assess, diagnose, and treat problems off-site with the help of virtual technology. And industry experts know it.

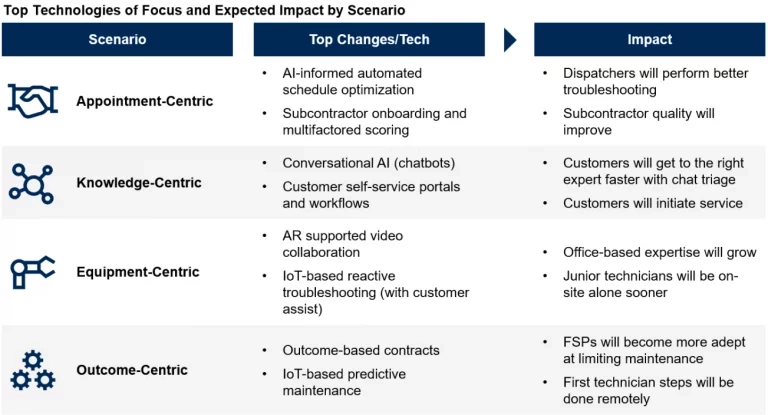

In its 2023 State of Field Services report, the Technology & Services Industry Association (TSIA) concluded that virtual assistance tech will be key moving forward, stating:

“Pre-pandemic, connecting equipment was viewed as near impossible. However, within weeks, IT professionals figured out how to move an entire workforce to a work-from-home model, and suppliers began to understand the value of telemetry to their operations.”

TSIA’s multimember study found 38% of companies now use remote assistance services as a standard part of their technical support and maintenance contracts.

Research firm Gartner arrived at the same conclusion, stating video technology would be important for the future of equipment-centric field service work.

There are times when a truck roll is necessary. On some occasions, only the tech is going to have the proper tools to fix the problem. If someone needs cable installed for their WiFi system, for example, you don’t want the customer doing that.

But virtual assistance tools can both reduce and optimize truck rolls by allowing techs to solve simple problems remotely and ensuring they have the proper equipment to fix issues that require a dispatch.

We’ll cover how virtual assistance tools can help later in this piece. But first, it’s important to see how much a truck roll can cost and why it’s critical to reduce unnecessary runs.

Cutting costs won’t help much if it impacts the level of service your business provides. Luckily, there are ways to shift the time and effort spent on typical truck rolls into more productive areas.

Remote visual support (RVS) technology is a great way to reduce truck rolls. This tool, also called remote visual assistance (RVA), allows techs to see the environment through a video feed and help the customer with any problems that are too minor to justify a service call.

RVS technology also often has augmented reality (AR) elements built in that help even more. That could be something as simple as drawing on the image to show where the problem is in real time so a customer can better understand what the tech wants them to do. To see that in action with Apizee, check out this video.

We’ve seen this technology help businesses in the real world. International equipment rental company Kiloutou chose Apizee’s video assistance solution to strengthen its remote technology presence and attain its sustainability goals. In Kiloutou’s French headquarters, nearly one in seven service calls now occur remotely.

Kiloutou was able to see a significant boost in their stats using this technology, including:

And they’re not the only ones. According to data from Apizee’s customer businesses:

Video support can also help your staff assess their needs and schedule smarter.

Being more efficient with your scheduling practices can optimize the truck rolls you do have to send out. Simple measures like ensuring multiple appointments are in the same geographic area reduce fuel costs and wear and tear on the fleet.

You can even group customers in the same area together, then assign certain techs to those groups. Groups located near one another — say within 50 miles — also reduce travel time and expenses.

Depending on your industry, the size of a customer group, also called a cluster, will vary. A retail cluster would need a different approach than one for the manufacturing or telecom industry, so think through the logistics of where your customers are if you want to try this approach. Make sure you have enough people to serve the area without overloading them.

Beginning every service call with a virtual assessment is one way to be more efficient. If it’s a minor issue, the tech can help the customer solve the problem without dispatching to their location. If they have to leave, a pre-visit assessment ensures they have the proper equipment with them to fix the problem the first time out.

Start by optimizing your pre-call assessments for efficiency. That might mean including a request form on your website where people can start by outlining the problem, then a customer service rep following up on that form for more details.

From there, the customer rep hands the call off to a technician, using video support to outline the problem. They can use remote video to better diagnose the issue and guide the customer to a solution. If necessary, they can gather the proper tools and travel to the customer with a better idea of what’s going on than if they went in without that information.

Whether the technician can diagnose the problem remotely or has to travel to the site, it’s more likely to go right the first time with a good pre-call assessment.

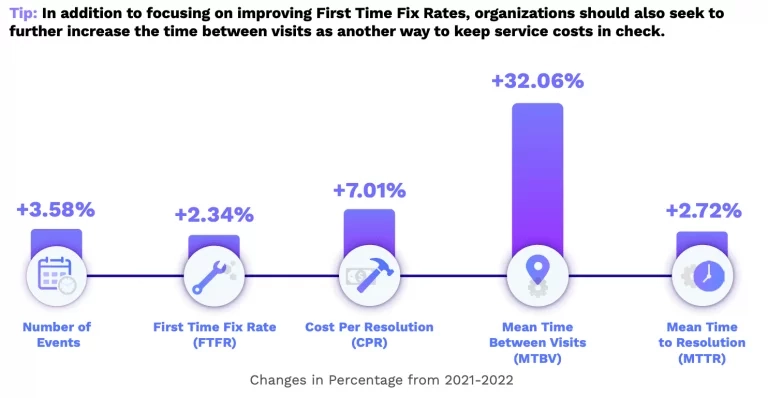

Increasing your first-time fix rate saves money, improves customer satisfaction, and increases the time between calls, a metric almost as important as first-time fix rate according to Aquant’s 2023 Field Service Benchmark Report.

Source: Aquant Field Service Benchmark Report

Inversely, a truck roll that doesn’t lead to a first-time fix can mean up to 2.75 total site visits and almost two weeks added to resolution time.

Companies are at their best when everyone communicates well. When all the departments within a business understand how best to work with one another, everything runs like a well-oiled machine. But if information gets siloed unintentionally, the opposite can happen.

When a customer service rep asked field technicians on Reddit what they’d like to see happen more on calls, they mentioned:

Communication breakdowns can cost as much money as an unnecessary truck roll, draining time and effort. Techs end up budgeting more time for the work than necessary and have to spend time correcting work orders when they’re entered incorrectly elsewhere. In Grammarly’s 2023 State Of Business Communications Report, the company found that miscommunication cost respondents a total of over $1 trillion annually.

To avoid miscommunication, put policies in place that let your customer reps find out as much information as possible. Talk to your technicians and find out what they need to know and how they want to receive that information. For example, in the Reddit thread mentioned above, many technicians said more detailed written information would help.

Techs and reps staying on the same page can also help reduce equipment costs. If a rep thinks a field tech has five modems in their vehicle ready to go when they only have three, that rep might put in an order for a modem replacement that doesn’t need to happen — and leave that tech short if they come across a part that really does need replacing.

Techs, customer reps, and dispatchers should all understand what the other parties need and want. Make sure your staff is talking to one another and on the same page.

To help that process, call a meeting with your staff to get input on what they need. Have them ask one another what they can do to help. Then take that information and make it company policy so it becomes part of the way your business works.

Good internal communication can also help decrease customer churn. If your company communicates well, it’s more likely to run well. When that happens, problems get solved efficiently and the customer experience is more positive.

Scheduling calls manually takes time and effort away from the real work. And you don’t have to do it that way anymore.

Using software to route calls to the nearest available tech automatically helps reduce unnecessary truck rolls. It also makes life easier for your techs in the field. An artificially intelligent support ticket software like Capacity can create tickets, collect info with a chatbot, and transfer the ticket to a person if the call becomes more complicated.

Recent contact center automation trends enable you to route calls to techs with a particular skill set, so the best person to handle the job is the one that gets the call. For example, if an engineering company is having problems, an automated system can assign the call to a tech with relevant background.

Ensure the data is correct and people are talking to each other because having to backtrack and correct erroneous information negates any advantage you might get through automation.

Having an internal knowledge base that techs can use in the field makes the difference between an extra trip and a first-time fix. Remote assistance also allows more experienced techs to provide hands-on training to new hires, even if they can’t be there in person.

The knowledge base should have:

A public knowledge base for customers can also reduce truck rolls if it lets people troubleshoot problems without having to call a rep.

Host how-to videos for common problems, walkthrough articles and explainers, and instruction manuals on your website. Make them easy to find. These tools won’t eliminate the need to go on-site completely, but they can reduce NFF and unnecessary truck rolls drastically. Apizee, for example, has user guides and video tutorials in its help section.

According to a survey by Nclarity, the true monetary cost of an individual truck roll can be around $1000, never mind multiple dispatches in a day or a week.

Direct and indirect expenses incurred for each dispatch include a variety of factors. The first is labor cost. That’s money paid to the technician, along with the cost of travel to the site and the administrative expenses involved with the call.

Unnecessary calls also incur an opportunity cost. The technician’s time spent on a call they didn’t need to make could’ve gone toward something more productive.

Then there’s the vehicle cost. Each truck roll puts wear and tear on fleet vehicles, and the cost of gas also adds up the more miles get driven.

Machine downtime is another, often overlooked consequence of a failed first-time fix. If a technician goes to the site to assess a problem without the proper tools to fix it and has to make a second trip with the right equipment, that can add hours or days to repair time. In a professional industrial setting, that translates to increased expenses, lost revenue and lots of people potentially going without a needed service.

Say your average first-time fix rate is 75%. That means for the other 25% of truck rolls that go out, the tech will have to make another run. If your company makes 500 dispatches a day, that’s 125 calls requiring a second run. That becomes an expensive problem quickly as costs balloon to $1,000 per truck roll.

There are also “no fault found” (NFF) dispatches. NFFs are simple problems that techs can solve without being on-site. They usually take less than five minutes to diagnose and fix in the proverbial “turn it off and back on” scenario.

A simple formula to determine how much you’re spending on truck rolls is to take the average cost of a truck roll and multiply it by the number of dispatches you have per month:

Cost per truck roll X # of truck rolls in a month = Total spent on truck rolls per month

From there, you can take the number of NFF or unnecessary truck rolls and multiply it by the cost per truck roll to get the total you could be saving:

Cost per NFF dispatch X Cost per truck roll = Total potential savings per month

Remember: some truck rolls are necessary, so you’re likely not aiming for zero. But you can save a lot of resources with a more efficient assessment system.

You don’t have to guess how much money you could save by reducing truck rolls; we’ve taken care of that for you.

Our calculator will help you both determine the actual cost of a truck roll and see how much money you can save if you cut back truck rolls by a certain percentage.

You can lower truck roll costs on two fronts: reducing spend by sending fewer vehicles and optimizing those you do send out. That allows companies to save more. For one thing, it can help reduce customer churn.

If a tech has to come back to fix the same problem, it can impact customer satisfaction. People who had a negative experience with a company via their customer service department, techs, equipment, or some combination of factors aren’t going to stick around.

The data backs this up. Customer service expert Shep Hyken found in his Achieving Customer Amazement Study that 77% of people will leave a company that doesn’t respond when they have a problem.

If you can resolve problems the first time, or via video call without even having to go on-site, people are more likely to have a positive experience with your business. And that sets it apart from the ones not willing to make an effort.

Reducing truck rolls is also better for the environment.

Studies show the average carbon footprint of a truck is 14 times that of a person. Large, heavy vehicles spew more carbon into the air, so each mile they don’t have to drive is a little less greenhouse gas in the atmosphere.

For example, some of the biggest companies using Apizee have avoided an average of 34,000 unnecessary truck rolls. That translates to 6.7 million euros saved and keeps 60 tons of carbon dioxide out of the atmosphere.

Truck roll optimization also frees up time to work on more pressing problems. A tech can view, diagnose, and help a customer repair a minor issue over a video call in minutes.

That’s money, fuel, and time saved. Plus, your technicians can now help several other people in the time it would’ve taken to drive to a location.

With the Internet of Things (IoT) becoming more integrated with our daily lives through smart homes and appliances, more technical issues will arise. People with technical expertise who can solve these problems efficiently will be in high demand.

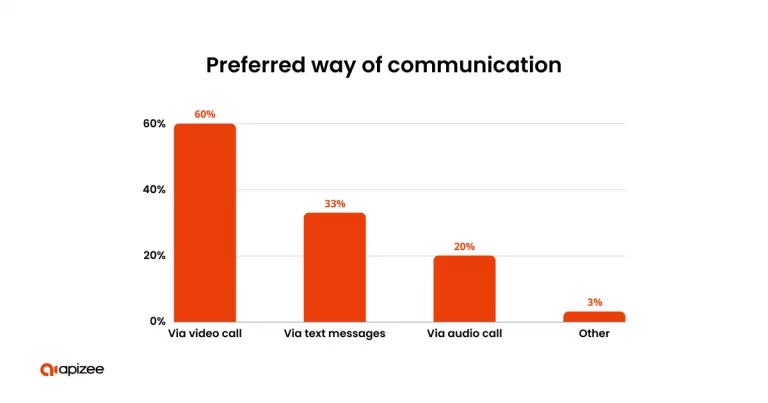

Remote solutions are also something customers want. In a market study by 3veta, 60% of respondents said they prefer to talk with their service provider by video call.

Source: 3veta

As technology advances, using it to solve problems virtually is only going to become more significant to field service operations.

Yes, a reduction in dispatches can lower your business’ carbon footprint significantly.

Studies show the average carbon footprint of a truck is 14 times that of a person. Large, heavy vehicles spew more carbon into the air, so each mile they don’t have to drive is a little less greenhouse gas in the atmosphere.

Companies using Apizee’s solutions have avoided 34,000 unnecessary truck rolls and counting. Not only does that translate to 6.7 million euros saved, it keeps 60 tons of carbon dioxide out of the atmosphere.

The amount will be different depending on the size and type of your business, the number of calls you take, and the type of vehicles you use, among other factors. The average cost per truck roll is estimated at anywhere from $200-$1000, so once you find out how many went out that didn’t need to, you can do the math from there — or use our handy calculator tool above.

The top reason time gets wasted on a truck roll is inaccurate diagnosis before rollout. Having to return to the shop for the correct tool, part, or equipment is another common reason, as is the lack of a first-time fix. Mitigate or fix all these problems with visual support technology.

As IoT and the devices we use evolve, technology will only become more essential to field service organizations and professionals. The companies that get on board now and learn to use it to their advantage will be the ones that benefit.

To learn more about how Apizee’s real-time video communication solutions can streamline your operations, schedule a free demo today.

Read also:

Explore key findings from the Genesys State of Customer Experience report. Learn how AI, omnichannel strategies, and video chat are transforming CX and enhancing customer satisf...

The State of Customer Experience report by Genesys : Key Insights and Trends

27 Mar 2025

Despite AI and automation, customers still prefer to speak to a human for support. Discover why human interaction remains essential for great customer service.

Why Customers Still Want to Speak to a Human in Customer Service

17 Mar 2025

Discover the top customer experience influencers in Europe, shaping the future of CX and customer service.

Top 100 Customer Experience Influencers to follow

10 Mar 2025

Interested in our solutions?