What is Remote Visual Inspection?

Offering Better Solutions to Customers & Users

Remote visual inspections can save time, highlight business priorities, and reduce your carbon footprint. Businesses using Apizee’s visual-assistance tools also saw a 40–50% reduction in technician travel costs, saving companies not just in fuel, time, and maintenance costs, but also in carbon emissions.

It may seem like a big mountain to climb if you’re getting started with remote visual inspections: there’s new technology to understand, regulations to follow, and logistics to consider.

In this article, we’ll explain what a remote visual inspection involves, the benefits of performing your inspections virtually, and how to conduct a successful remote visual inspection for your business.

Remote visual inspection (RVI) is an examination performed remotely by a technical expert. Sometimes known as remote digital video inspection (RDVI), the process involves using video-assistance tools to perform the inspection virtually.

Instead of being there in person, the expert can perform the inspection from another (and sometimes safer) location. For example, if the area of the inspection is in a hard-to-reach or hazardous area, the inspector puts themself in danger to perform the assessment in person. With RVI, they can do it from the comfort of their home or office.

In 2020, the hotel chain CitizenM began construction for a new hotel in Washington. During the pandemic, it wasn’t safe for building inspectors to attend worksites and perform their standard inspections. Instead, they began using RVI.

After getting approval from various governing bodies, they conducted the inspection virtually. Inspectors could check for leaks, review the pressure of supply piping, and verify that electrical cabling intervals connect to the right outlet boxes without being on-site.

Remote visual inspection also makes it easier for experts to access hard-to-reach areas and perform nondestructive testing. Think about offshore oil and gas companies as an example.

RVI provides a faster way for experts to ensure the technical security and performance of offshore projects and operations. Experts can collaborate in real-time with field staff working on location, which is often far out at sea or in remote areas.

It allows them to provide their support and expertise where it’s needed most without having to be there in person. The inspector also doesn’t have to travel to and from the inspection site, saving time and money.

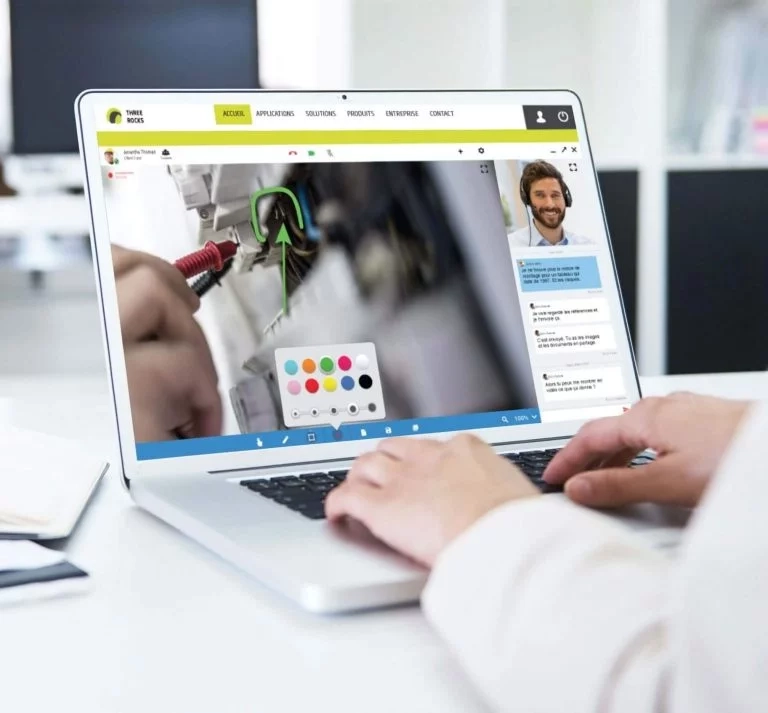

The exact process varies depending on the business, the industry, and the issue. In safe places, RVIs typically involve someone on-site using an inspection camera (such as a smartphone or a tablet) to show an expert around a piece of technology or equipment. The expert then performs the assessment virtually from wherever they’re working.

Other forms of RVI include:

Ultimately, the best tool for the job depends on where the inspection is taking place and the object or place that is up for inspection.

For example, if someone’s having trouble setting up a new laptop, a smartphone will suffice. Crawlers are ideal in unsafe situations around large equipment, such as a nuclear reactor, whereas video borescopes are well suited to hard-to-access places, such as in foreign object search and retrieval (FOSAR) operations.

During the inspection, experts may take snapshots, pause the camera, and zoom in on certain areas to get a better look. Recorded media from these inspections can be used as part of the final inspection report (we’ll talk about this in more detail later).

Take a look at robotics academics used RVI to perform predictive maintenance on infrastructures.

Bridges (and other similar infrastructures) require regular maintenance and inspection due to the potential for property destruction, injury, and even loss of life due to damages.

The engineers and academics in the study struggled to successfully perform the inspections. Here are a few of the other challenges they faced:

Source: MDPI

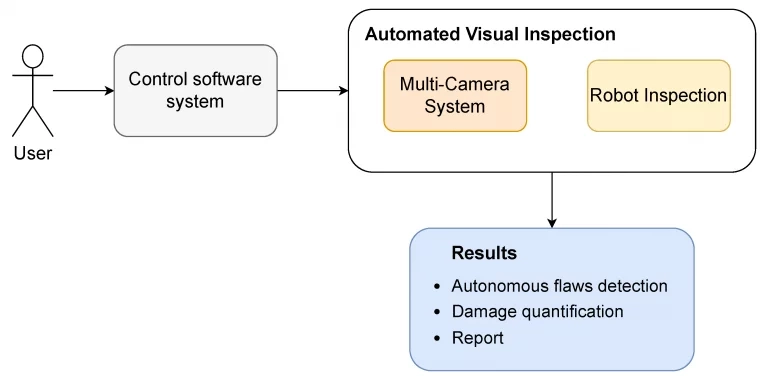

To overcome these challenges, they devised a remote visual inspection system.

The system uses a drone to film different areas of the bridge. An expert reviews the footage for corrosion, damage, and anything else that might predict potential issues.

Here’s how the system works:

It allows the assessor to provide objective results while guaranteeing their safety. Not to mention, it also prevents bridge closure and speeds up the entire inspection process.

A single operator is still required on-site to make sure the inspection runs smoothly. But using drones, technicians and experts can conduct the inspection safely over a large surface area.

Let’s outline some of the benefits that come with using remote visual inspection.

Here, we’ll cover some of the most common situations when using a remote visual inspection is the right course of action.

Assessors can use an RVI to review technology and equipment in line with guidelines and industry standards. As a result, they’re able to make sure that everything is safe and compliant with any relevant regulations.

Take a look at the Global Marine Consultants and Surveyors (GMCS) as an example.

Using Apizee’s video-assistance tool, GMCS performs offshore vessel inspections. With our video communication features, GMCS provides effective and secure remote inspections to improve safety when issues arise at sea.

Getting the detail and quality you need from inspection reports can be tricky when it comes to hard-to-reach and dangerous locations. Assessors might not be able to conduct a thorough report due to safety risks and limitations.

With remote visual inspection, this isn’t an issue.

Technical experts can perform thorough inspections of hard-to-reach areas from a safe location. Whether it’s by drone or a front-facing camera being held by an operator, the assessor can review all the information to provide a detailed inspection report.

A risk assessment involves identifying and managing financial or physical risks to the business.

With RVI, experts can carefully review any potential risks and suggest preventive measures to keep customers and employees as safe as possible.

SAFed (Safety Assessment Federation) provides a good example of how RVI can support risk assessments.

The organization uses RVI to perform examinations on pressure equipment. Their inspection service involves reviewing certain boilers and pressure vessels to ensure they’re adequately equipped for cleaning and repair.

With RVI, the company can review parts of the equipment that might not be analyzed otherwise. It allows them to perform a thorough risk assessment and ensure that the equipment they inspect is safe to use.

Performing a remote visual inspection is a different process to conducting an inspection in person. Take a look at the following steps to ensure your next remote visual inspection runs as smoothly as possible.

For a business to function legally, it must abide by certain laws, regulations, industry standards, and ethical conduct standards.

When it comes to performing a remote visual inspection, it’s vital that you know what these compliant requirements are. If something isn’t compliant, you can flag it.

As an expert, you’re probably already aware of the relevant compliance requirements — but it’s best to be as thorough as possible. You need to be sure that the inspection covers all the relevant regulations to ensure customer and employee safety (and to avoid unwanted fines).

Compliance requirements vary based on industry and location, so review the regulations that are relevant to the inspection you’re performing. This means outlining all the legal standings you must follow (e.g., not disturbing a nesting creature), the industry standards you must meet (e.g., health and safety guidance), and any other rules you need to follow (e.g., security protocols).

It’s helpful to create a list of these requirements to refer to throughout the inspection. Depending on the software you use, you can often create a checklist to use while performing the inspection (more on this later).

To make sure the inspection runs as smoothly as possible, be sure to test your software beforehand. If there are any glitches or errors you need to address, you can do it before the inspection begins.

Here are some of the areas to test before the inspection.

Whatever type of camera you’re using, do a test run to make sure everything’s working. Check that both the sound, video, and image quality are working well. You don’t want to get to the top of a wind turbine and discover the camera is out of battery, for example.

Testing your cameras is particularly useful when using technical RVI equipment like a drone or endoscope. It’s harder to replace on the day, so you want to make sure it’s working as it should. If a smartphone camera isn’t working, it shouldn’t be too hard to source a replacement.

Depending on your virtual inspection software, you may have access to additional features. For example, Apizee users can make notes and annotations in real time while the video inspection is underway.

If this feature doesn’t work on the day, it could prevent you from making notes throughout the inspection. To avoid this happening, make sure to test any features before the inspection takes place.

Attempting a video call with weak internet signal is frustrating. To ensure you have a high-quality connection for the inspection, test it beforehand. Run a quick video call from the location of the inspection to see how it performs. If it doesn’t work or if it lags, you can get in touch with your internet provider to put things right.

Every inspection is different, so there’s no single step-by-step guide on how to conduct a remote visual inspection.

However, to give you an idea of what happens during an inspection, we’ve outlined the key steps for inspecting the construction of a new house. In this example, an employee is on-site with a helmet-mounted camera.

When the inspection is over, the participants simply leave the video call. The inspector can then review the information and start drafting the inspection report.

When the inspection is over, draw up an inspection report with your findings and suggestions for improvement.

Here are some best practices to keep in mind while writing the report:

Past inspection reports can be incredibly useful for future inspections. They outline what’s happened in the past, the changes that have been made, and whether past recommendations have (or haven’t) been listened to.

It’s also important to have a record of inspections should any claims or liability issues arise. For instance, if a piece of equipment fails and causes damage, you want a record of your inspection to prove that you aren’t liable.

That’s why it’s important that you store and archive all of your inspection reports. It sets a benchmark for future inspections and keeps everything on record.

If you’re not sure how best to store your inspection reports, a document management platform is a great place to start.

Document management software is a system that receives, stores, tracks, and manages all the documentation for your business. It provides easy access to your documents and helps you organize them efficiently.

Cloud-based platforms like Dropbox, Oodrive, and Google Drive are all examples of document management platforms, each with its own merits. If digital sovereignty and data security are important to your company, choose a platform that is based in your location and transparent about its protection methods.

Businesses looking for a more comprehensive solution can look to store their reports in a secure CRM (a customer relationship management system). Tools like Pipedrive, Salesforce, and folk help teams communicate internally and manage operations while offering a central storage location for notes, contact history, emails, and more.

If you’re ready to invest in an RVI solution, here are some key features to look out for:

To save you time finding a platform that offers all these features, take a look at Apizee.

Our remote visual inspection tool includes these features and more. Apizee makes it simple to get started with RVI and goes a step further by helping inspectors after the examination. Apizee walks you through the inspections with customizable checklists and then automatically generates inspection reports when finished.

Aircraft engine manufacturer Safran avoided €2 million worth of heavy maintenance using a web-based platform powered by Apizee. The company’s Executive Vice President, François Planaud, told us:

“This solution has helped to save millions for ourselves and our customers thanks to live data exchange reducing decision-making time from days to hours. In some circumstances, situations have even been resolved instantaneously.”

Find out more about our video-assistance tools or get in touch for a free demo.

Remote visual inspection has some clear advantages over traditional inspections. It saves you time, minimizes travel costs, reduces your carbon footprint, and allows technical experts to assess hard-to-reach areas.

To successfully conduct a remote visual inspection, you need the right visual-assistance tools in place. Apizee’s video-communication software allows your experts to perform safe, efficient virtual assessments from anywhere.

Contact us today to learn how Apizee can help you set up remote visual inspections.

Explore key findings from the Genesys State of Customer Experience report. Learn how AI, omnichannel strategies, and video chat are transforming CX and enhancing customer satisf...

The State of Customer Experience report by Genesys : Key Insights and Trends

27 Mar 2025

Despite AI and automation, customers still prefer to speak to a human for support. Discover why human interaction remains essential for great customer service.

Why Customers Still Want to Speak to a Human in Customer Service

17 Mar 2025

Discover the top customer experience influencers in Europe, shaping the future of CX and customer service.

Top 100 Customer Experience Influencers to follow

10 Mar 2025

Interested in our solutions?